The first step towards the data driven transition?

This versatile data acquisition unit features a powerful on-the-edge AI microservice integrated into its hardware infrastructure

Enabling easy integration, data acquisition, and real-time monitoring from both modern and legacy industrial machinery.

It provides immediate support to production processes by extracting data from machines to gain visibility into production, costs, and energy consumption.

It is compatible with a wide range of industrial sensors, which can be configured independently using the No-Code Configurator.

This versatile data acquisition unit features a powerful on-the-edge AI microservice integrated into its hardware infrastructure

Enabling easy integration, data acquisition, and real-time monitoring from both modern and legacy industrial machinery.

It provides immediate support to production processes by extracting data from machines to gain visibility into production, costs, and energy consumption.

It is compatible with a wide range of industrial sensors, which can be configured independently using the No-Code Configurator.

Advanced Technology

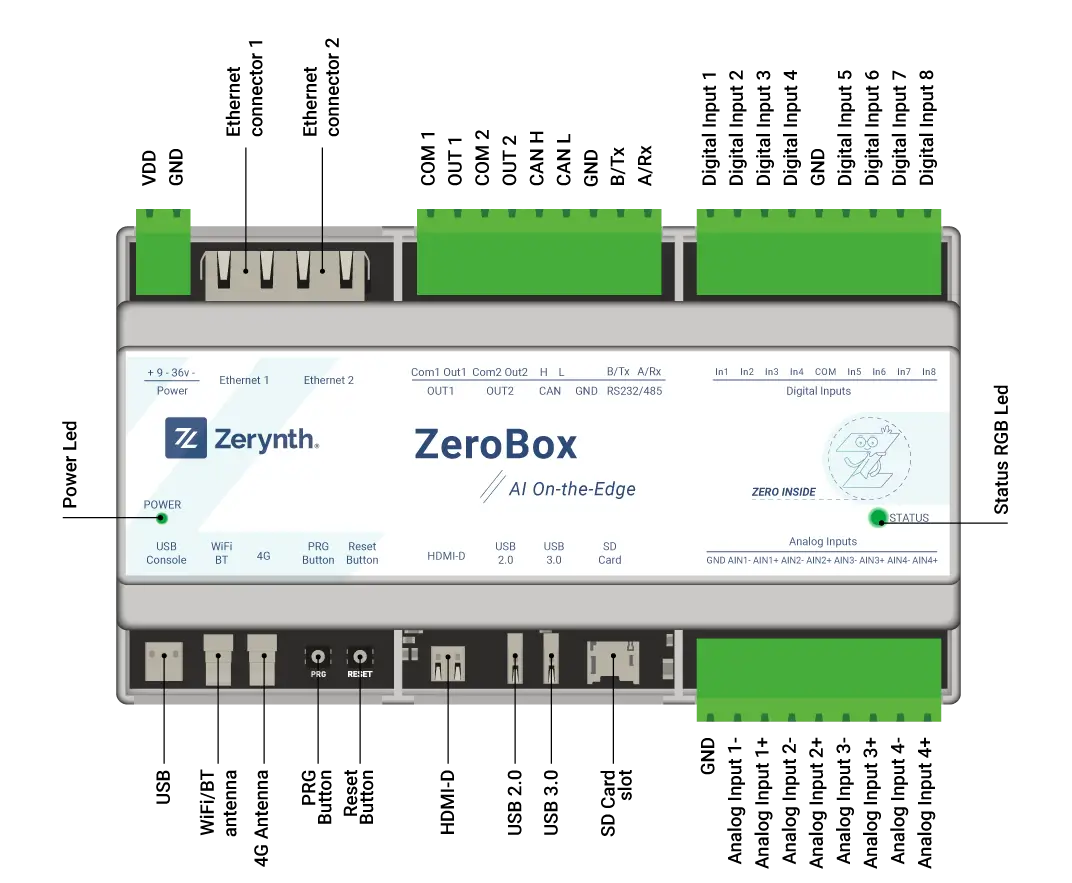

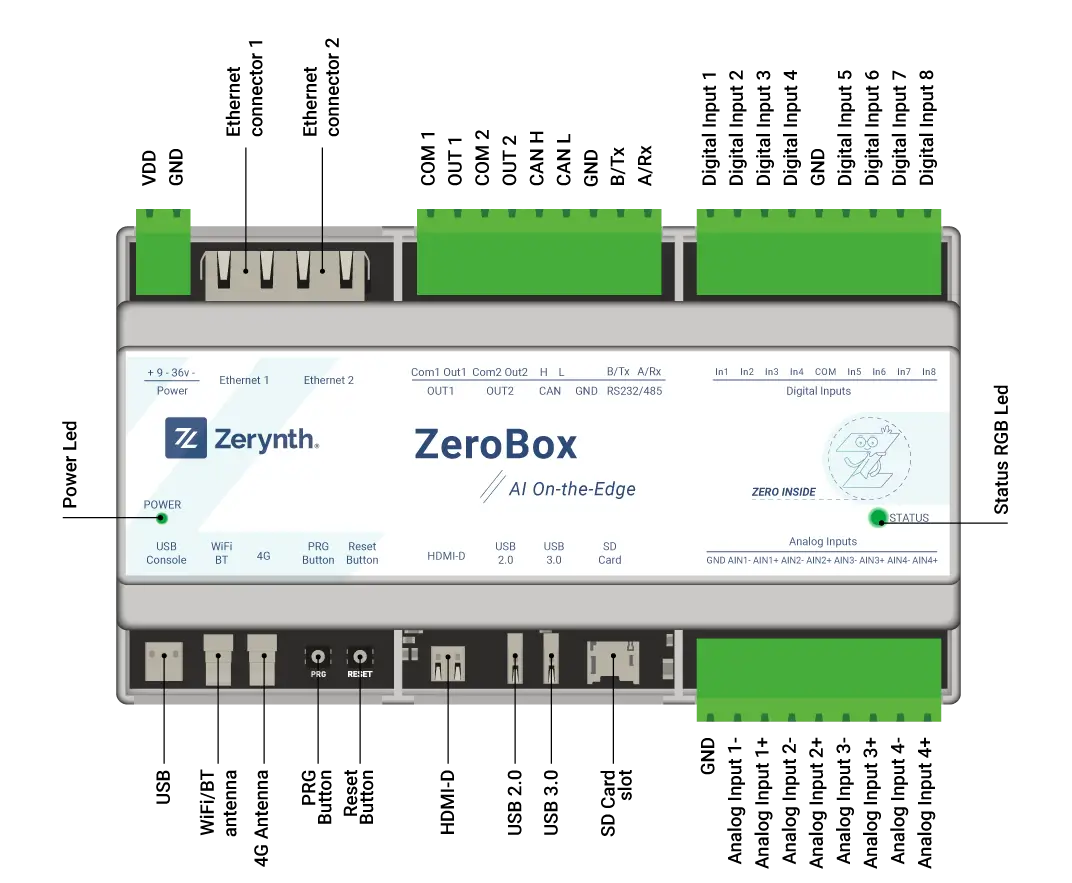

Industrial-grade hardware architecture based on a Quad-core Cortex-A55 microprocessor, enabling the execution of data acquisition, filtering, and analysis algorithms directly on the device.

Integrated Artificial Intelligence

The system acquires data from connected sensors and machinery, processing it on the device for rapid anomaly detection.

Connectivity and Interfacing

Z-Edge Insight supports a wide range of connectivity options, including Wi-Fi, Ethernet, and 4G, ensuring reliable and versatile connections with existing devices and systems in the industrial environment.

Maximum Data Security

Data transmissions comply with the highest industrial standards, featuring data encryption, secure authentication, and support for dedicated hardware elements to safeguard sensitive information.

INDUSTRY 5.0 READY

Natively designed to include energy consumption analysis within the monitoring of production processes, it qualifies as capital goods in group 2 and meets Industry 5.0 requirements.

KPIs Calculated

- Energy consumption profile

- Machine status (working/idle) with derived statistics

- Production output (good and defective pieces)

- Cycle times with derived statistics

- Alarm times and derived parameters (MTBA, frequency, and duration of alarms)

- OEE with subcomponents (Availability, Performance, and Quality)

- Energy cost per machine and per piece produced

Functionalities

- Gain real-time insights: Capture valuable data from your machines using integrated sensors.

- Improve production: Make informed decisions based on the collected data.

- Reduce costs: Enable predictive and condition-based maintenance, eliminating unnecessary expenses.

- Access Italian's tax incentives.

Applications

- Production efficiency optimization

- Energy consumption monitoring and optimization

- Retrofit of industrial machinery

- Condition-based and predictive maintenance

- Machine and industrial asset monitoring

- Production order visibility and tracking

Want to learn more?

Contact us for any questions or clarifications: you will be contacted immediately by a member of our team!