Sibyl offers a 3-step process that includes Risk Analysis, IoT devices and sensors <br>specification, and the Sibyl platform for predictive maintenance.

Sibyl Risk Analysis

On-site study following criticality and cost criteria to identify the equipment: objectives, failure modes and necessary signals.

IoT Sibyl

Reliable data collection and transmission of the necessary ones, using existing infrastructures (e.g. PLC) and/or installing new sensors in the asset in question (including accelerometers, acoustic sensors, torque and force sensors, temperature and flow meters).

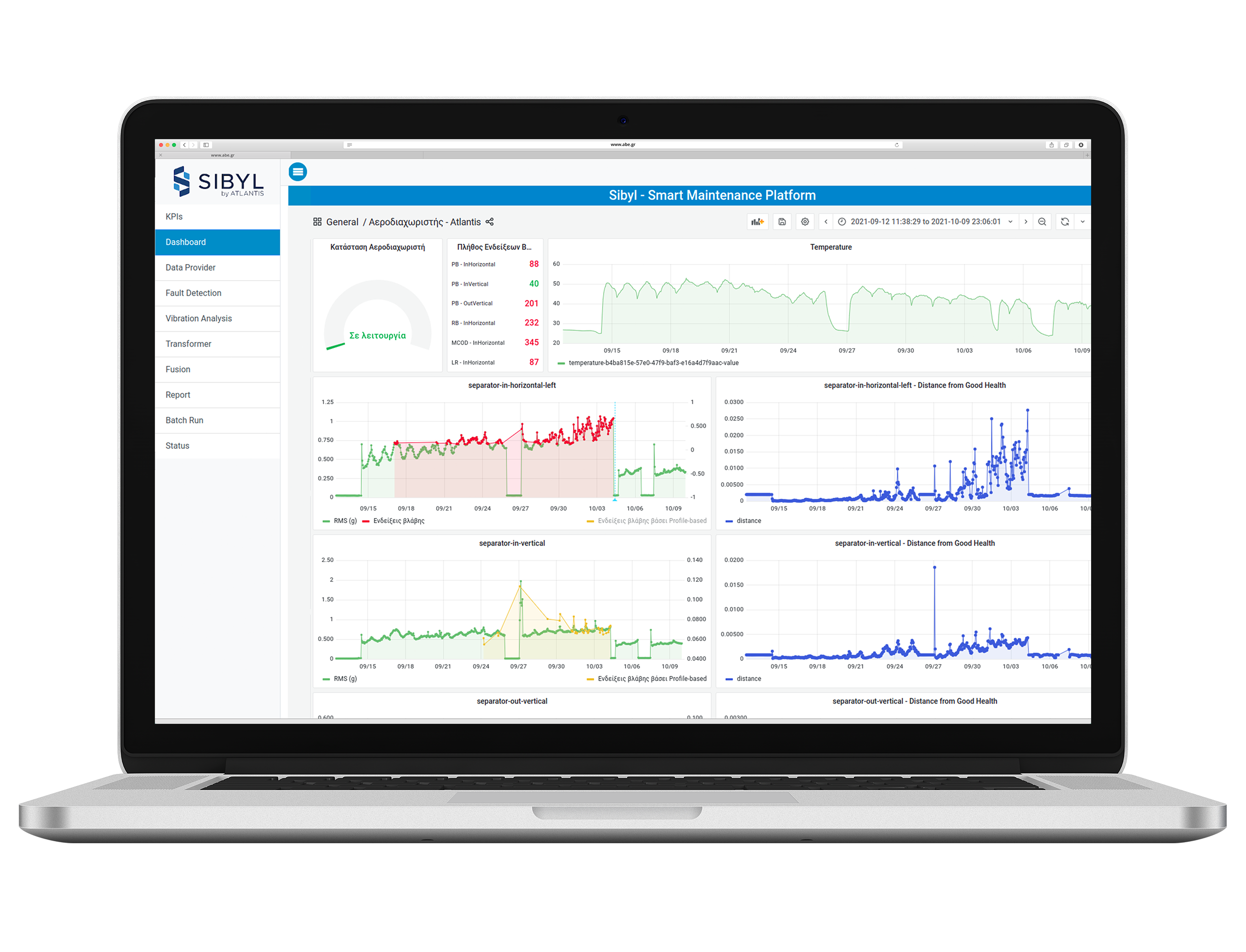

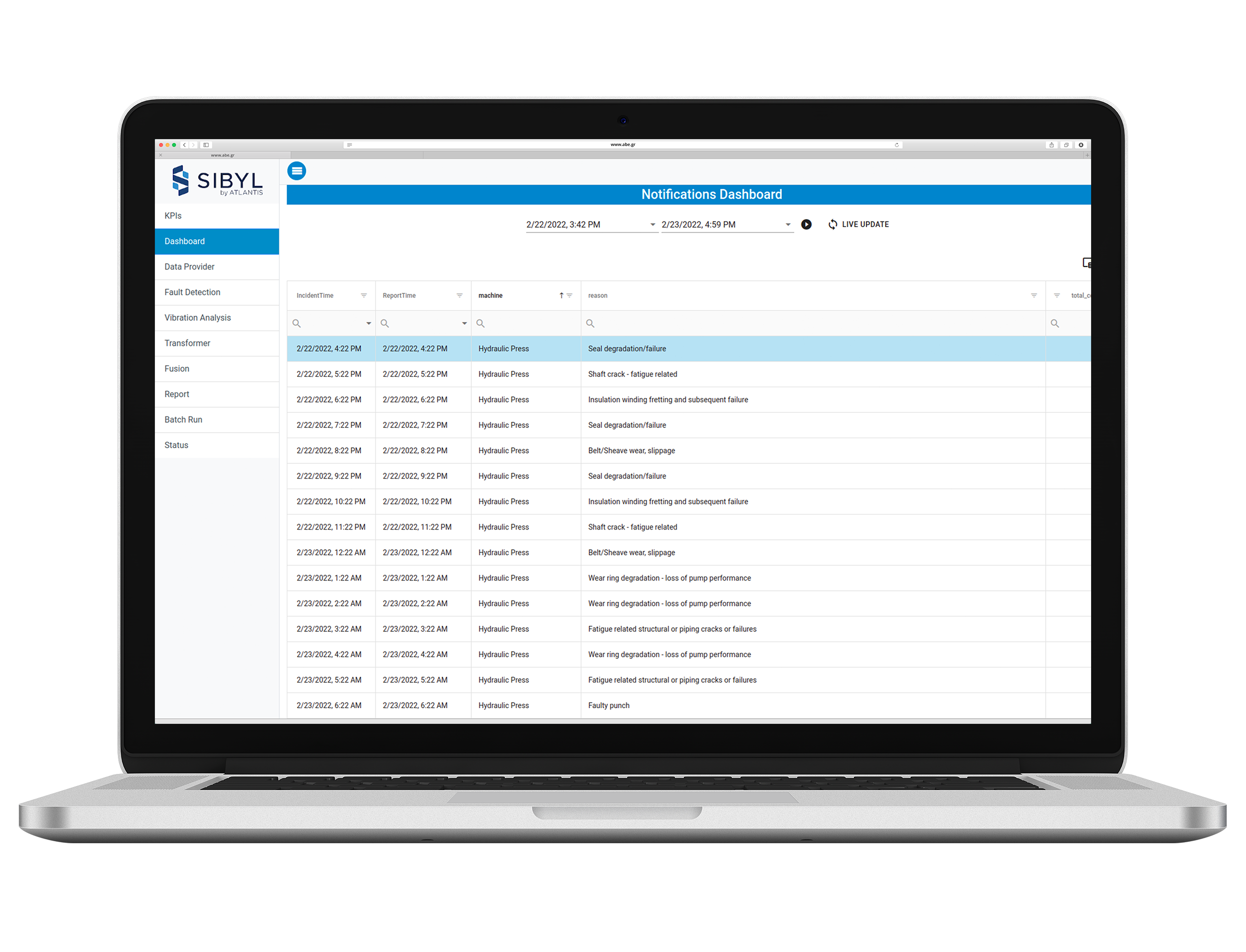

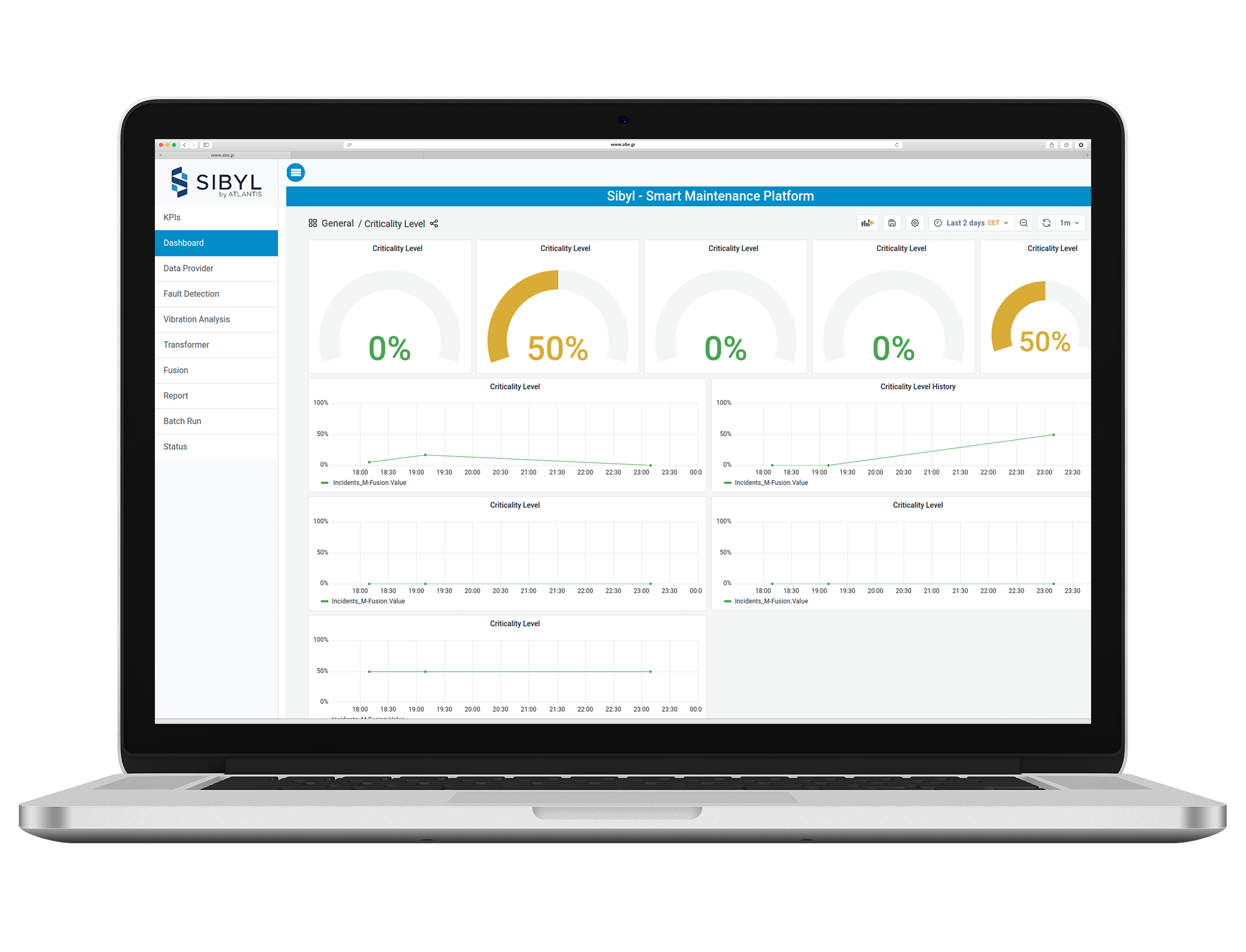

Sibyl Platform

The Sibyl Platform leverages the power of artificial intelligence and machine learning to transform large amounts of sensor data into actionable information.

Improved equipment uptime

By predicting when equipment is likely to fail, predictive maintenance allows for proactive maintenance to be scheduled before a failure occurs, improving overall equipment uptime.

Reduced costs

Predictive maintenance can reduce costs associated with unplanned downtime and emergency repairs.

Prolonged equipment lifespan

By identifying and addressing potential issues

before they become critical, predictive maintenance can prolong the lifespan of

equipment.

Increased efficiency

Predictive maintenance allows organizations to schedule maintenance activities when it is most efficient to do so, rather than on a fixed schedule.

Improved safety

Predictive maintenance can help identify potential safety hazards and address them before they become an issue.

Better use of resources

Predictive maintenance allows organizations to use their resources more efficiently by identifying and addressing potential issues before they become critical.

Zero defect production

25% Increase in production time without faults.

Predictive maintenance

Identify faults in mechanical equipment in up to 72 hours ahead of time.

Data Integration

Fuse data from different sources to solve non standardized problems.

Sibyl is a predictive maintenance platform that uses a microservices architecture and Industry 4.0 technologies.

With multiple features using machine learning techniques, Sibyl analyzes and extracts knowledge from data from various sources in the manufacturing process.

Fault Detenction

By utilizing a combination of multiple algorithmic approaches, Sibyl is able to detect a wide range of failure modes.

Fault Identification

By making use of sophisticated pattern recognition techniques and historical data, Sibyl efficiently matches footprints of known failure modes to live

sensor measurements.

Failure Prediction

Tailor the forecasting horizon to your production process needs by utilizing time series prediction techniques or recognizing hidden event sequence patterns.

emaining Useful Life (RUL) Estimation

Gain insights into the remaining lifespan of your assets and take proactive measures to optimize their performance.

Integration of Sibyl with Cmms

Integration with CMMS systems is simple. Bi-directional communication with CMMS systems, allows automatic generation and scheduling of tasks for technicians to mitigate a detected or predicted problem in the machinery or direct reporting of planned or extraordinary maintenance work from CMMS to Sibyl for data enrichment and continuous model optimization.

Want to learn more?

Contact us for any questions or clarifications: you will be contacted immediately by a member of our team!